- Office Hrs: 8:00 am to 5:00 pm

- 02-9972-0155

- 1800-611-332

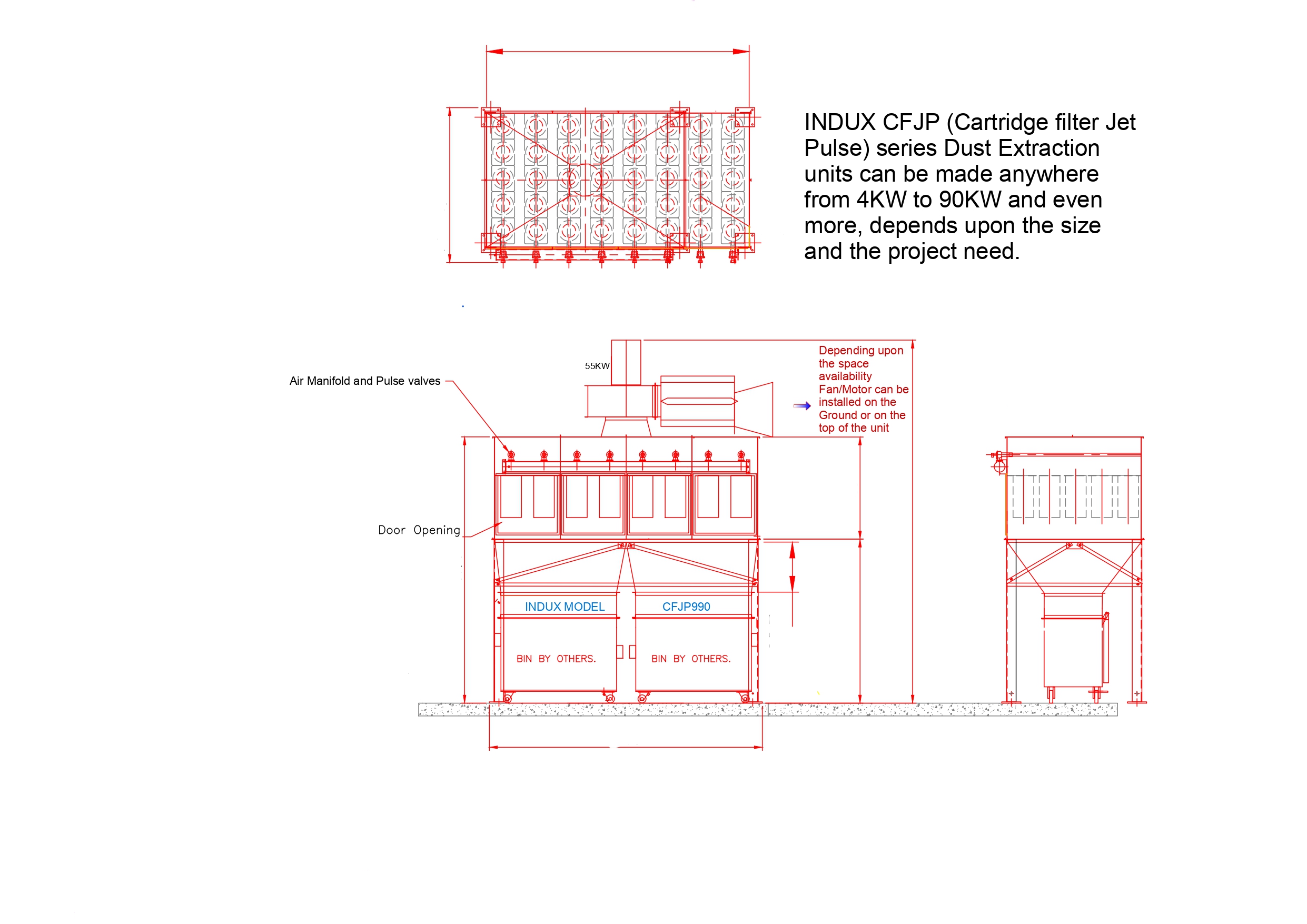

CFJP Series With Cartridge Filters

More Reliable because of 100% Australian Made products.

The CFJP filter series is specially engineered for extended service life with minimal maintenance requirements, tailored to extract a wide range of dust particles from various operations like polishing, grinding, and buffing. This versatile system effectively filters dust particles spanning from 0.5 micron to sizes exceeding 100 microns.

This advanced filter unit comprises cartridge filters equipped with a programmable top-mounted pneumatic cleaning system, ensuring optimal filter performance through automated and controlled cleaning processes.

The filtration process involves polyester antistatic filter cartridges securely attached to a cell plate. Dust-laden air enters the hopper section and filter plenum, where heavier particles settle into dust bins, while finer dust is captured by the filters, allowing clean air to pass through to the fan.

A noteworthy feature of the system is the innovative cam lever filter sealing system, facilitating effortless filter removal and replacement without the need for specialized tools, enhancing user convenience and maintenance efficiency.

SIZE / CAPACITY AVAILABILITY

Being a local Australian company, we possess the flexibility to design units of the CFJP series to match industry demand, tailoring them to any required size or specifications. The versatility of the CFJP series lies in its adaptability to various industries, allowing for customization based on specific industry requirements. Our units have been successfully deployed across a wide range of sectors, including mining, demonstrating the effectiveness and applicability of our solutions across diverse industrial applications.

FILTER CLEANING

The cleaning mechanism operates by employing jet pulses of compressed air, utilizing the venturi effect at the top of the filter cartridge to enhance cleaning efficiency. The compressed air pulses are precisely sequenced and timed by a programmable solid-state PCB controller to ensure effective cleaning of the filter cartridge while retaining a fine layer of dust as a pre-filter coating.

IMPROVED FILTERING EFFICIENCY

The CFJP series incorporates a well-balanced ratio of filter surface area to airflow, leveraging the high permeability of polyester filter media. This design choice leads to minimal pressure losses within the system, ultimately translating to cost-effective operation when compared to traditional fabrics like cotton. The efficient design of the filtration system optimizes airflow while maintaining low pressure losses, contributing to economical operation and improved overall performance in various industrial applications.

SPACE SAVING

The CFJP filters have been meticulously designed to prioritize efficiency and compactness, ensuring that the overall size remains small relative to the expansive filter surface area. This strategic approach not only maximizes filtration performance but also minimizes the physical footprint of the filter unit, making efficient use of space while optimizing functionality for a wide range of industrial settings.