- Office Hrs: 8:00 am to 5:00 pm

- 02-9972-0155

- 1800-611-332

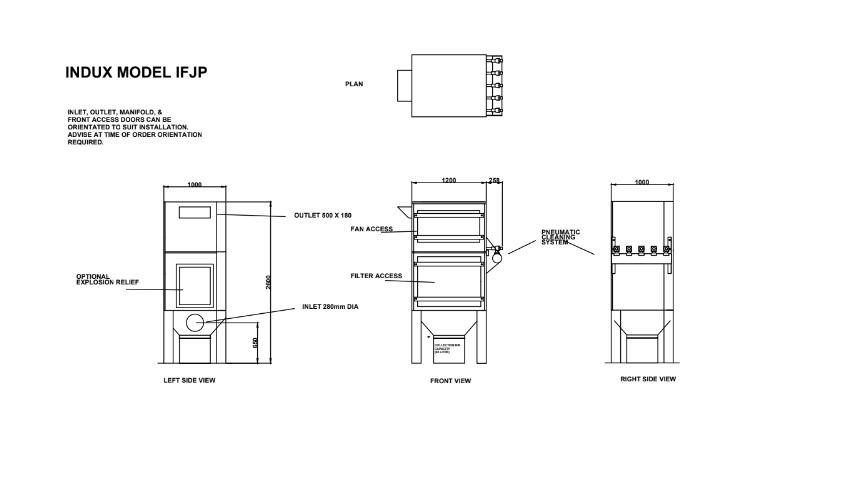

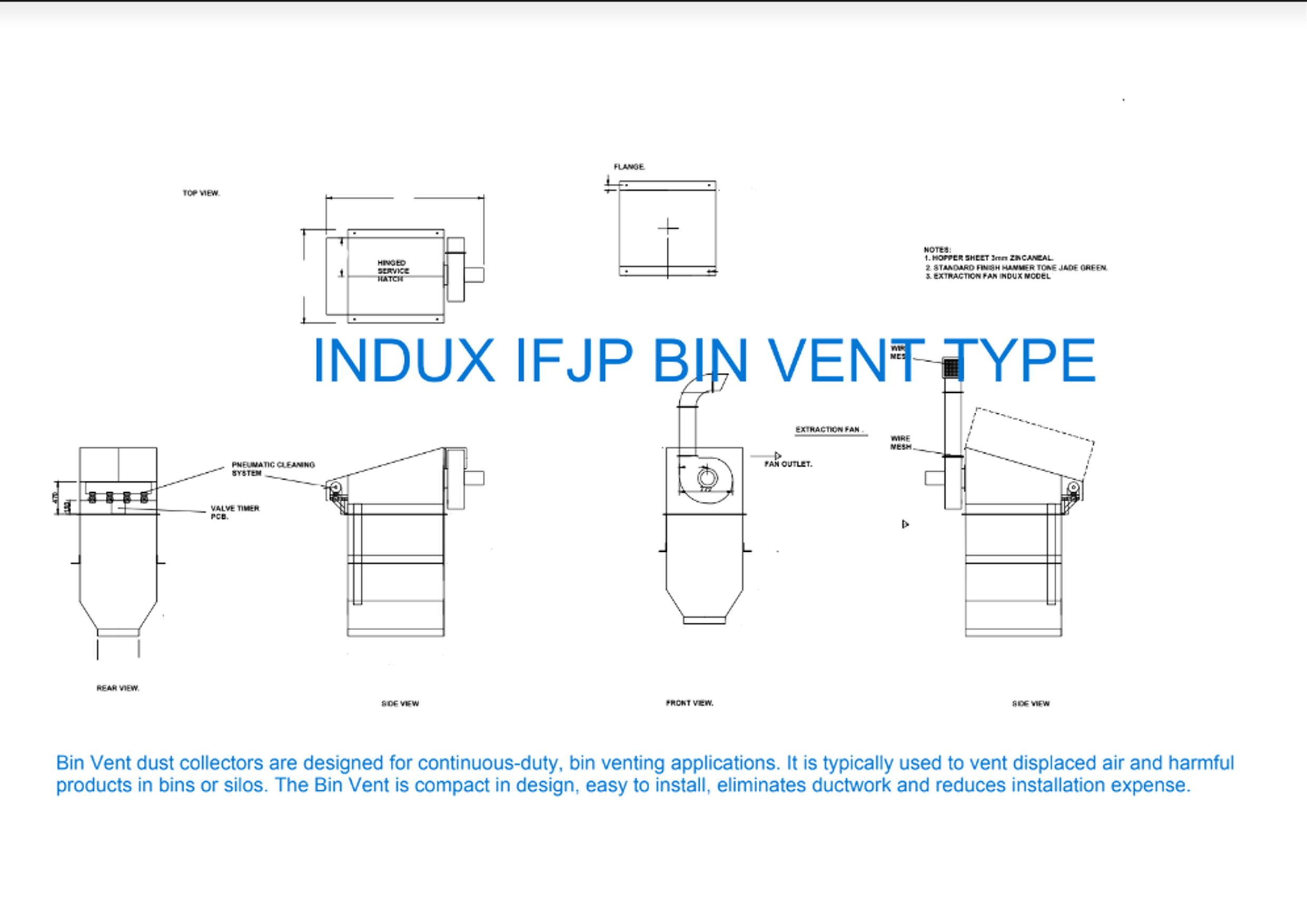

Indux IFJP Series with Secps Filters

INDUX IFJP SERIES

- HIGH PERFORMANCE

- REVERSE PULSE DUST COLLECTOR.

The INDUX IFJP series has been designed for a long service life with very low

maintenance requirements, it will extract fine to coarse dust from cutting, planing, moulding,

polishing, grinding, buffing and any other operation as required. It is suited to filter dust

particles from 0.5 micron to large size particles in excess of 100 micron.

The filter unit is a reverse pulse cleaning filter unit, which maintains optimum filter performance by

means of an automatically controlled compressed air cleaning system that cleans the filter sleeve

during operation.

The filtering is by means of a series of polyester antistatic needle felt sleeve filters, encasing steel

cages and connected to venturi tubes at the top and by sleeve support cap at the bottom held to a

plate via a spring.

Air is supplied from the outside of the filter sleeves to the inside and exhausts through the venturi

tubes into the top of the unit, exhausting to atmosphere.

Dust that is too light to fall directly into the collection bin builds up on the filter sleeves.

The specially designed venturis accelerate and inject a high-pressure air stream through the filter

sleeves releasing the dust-cake that has built up on the outside of the filter sleeves.

This is

performed by a set of solenoid control valves.

Recommended interval between pulses is XYZ seconds. However, the final pulsing programme

can be adjusted according to the type of dust being filtered, the amount of dust being drawn

through, and how quickly the filter sleeves build up a dust cake.

The extraction fan is situated on the clean side of the filter unit drawing air through it and

exhausting through a sound attenuation chamber to atmosphere.

On the side of the unit is a manifold air chamber which is connected to the solenoid control valves,

which are connected to the blow-tubes that sit above the filter tubes.

The solenoid control valves are controlled by an electronic sequential timer which opens the

solenoid control valves to allow a timed shot of high-pressure air through the filter tubes for the

purpose of cleaning the filter sleeves.

Space Saving

The IP filters have been designed with a view to keep the overall size small in relation to the filter surface area.

Sleeve Cleaning

The IP filters are designed to self-clean. This is achieved by the air flow through the sleeves from top to bottom, which improves the decanting of the heavier dust, while the lighter dust is separated by the filter.